Boyd Lab Equipment Guide

-

Bosch 12” Compound Sliding Miter Saw (GCM12SD)

Bosch 12” Compound Sliding Miter Saw (GCM12SD)

- Used for cutting wood only

- Vertical blade angle adjustable: 52 degrees left, 60 degrees right

- Built-in adjustable fences and clamps

- Crosscut up to 3 1/2″ by 13 1/2″ lumber

-

Laguna band saw (14|12)

Laguna band saw (14|12)

- Used for making either straight or curved cuts in wood and some plastics

- Table can be adjusted to a specific

-

Delta disc/belt sander (31-300)

Delta disc/belt sander (31-300)

- Multiple sanding surfaces for greater flexibility

- Not for use with aluminum

- Used to smooth corners, edges and for other light duty grinding

-

Ellis drill press (Ellis 9500 and Ellis 9400)

Ellis drill press (Ellis 9500 and Ellis 9400)

- Used for making holes in both wood and metal

- Digital spindle speed control

- Multiple clamping options for flexibility

- Many different styles of bits to choose from

-

DeWALT 12″ planer (DW735)

DeWALT 12″ planer (DW735)

- Can plane wood up to 12″ wide and a minimum of 12″ long

- Removes a small amount of material from the surface of wood to produce a very smooth surface

- Removes 1/16” maximum per pass

- Feeds wood through machine to control removal rate

-

Hegner scroll saw (Multimax-22V)

Hegner scroll saw (Multimax-22V)

- Used to create intricate cuts in wood and some plastics

- Adjustable head speed for different materials

- Table adjusts to specific angle from the horizontal

-

Baileigh oscillating spindle sander (OS-2424)

Baileigh oscillating spindle sander (OS-2424)

- Different size spindles available to match the curve being sanded

- Spindle moves up and down as well as spinning to ensure material is removed without burning

- Table can be tiled to accommodate for different angled features

-

Rockler table router (BMX61284)

Rockler table router (BMX61284)

- Used for hollowing and carving wood and some plastics

- Collet capacity: 1/2”

- Main body stroke: 2 7/16”

-

Sawstop 10″ industrial cabinet saw (ICS31230)

Sawstop 10″ industrial cabinet saw (ICS31230)

- Used for making many types of cuts in wood and some plastics

- Has specialized safety systems to reduce (not eliminate) the risk of serious injury

Dado Blade Set

A dado blade removes a larger width of workpiece material than a standard table saw blade. The number of internal blades, or “chippers” can be changed based on the desired width of workpiece material to be removed. A different brake cartridge must also be installed when using a dado blade set.

SawStop Brake Cartridge

The SawStop system charges the saw blade with a small electrical charge. When the electronics detect a small change in the charge, the brake deploys, stopping the rotation of the blade before serious damage to a user’s hand can occur. The second image below shows the deformation of the brake mechanism caused by the impact with the spinning saw blade.

New SawStop Brake Cartridge

Deployed SawStop Brake Cartridge

Metal working equipment

-

Baileigh slip roller (SR5016)

Baileigh slip roller (SR5016)

- Used to create a curve in sheet metal or wire with a minimum final diameter of 4 1/2”

- Not to exceed 50” wide 16 gauge mild steel

- 3” diameter rollers

- Adjustable for material thickness

- Can also roll wire in thicknesses of 0.513”, 0.407”, and 0.335”

-

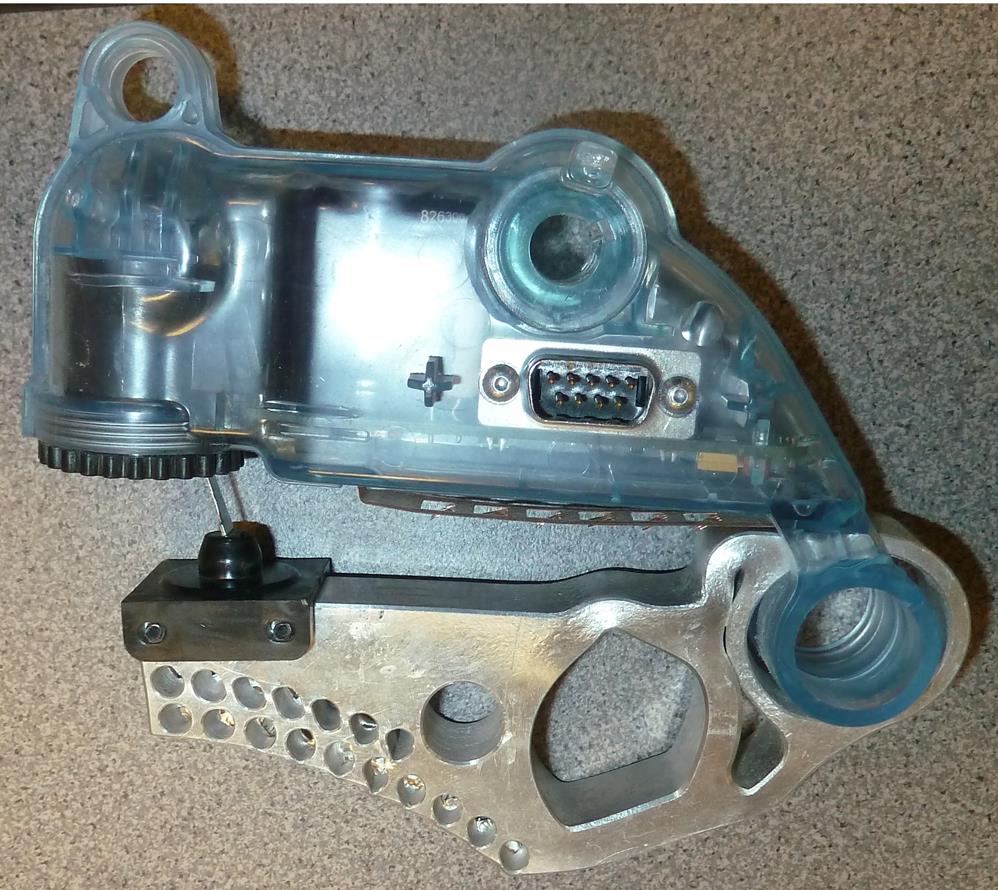

Bridgeport Knee Mill with Accurite G1 Control Unit

Bridgeport Knee Mill with Accurite G1 Control Unit

Used for manually machining components in 2D

- Can be used manually to create simple rectangular geometries

- Can be used semi-automatically with conversational control to do more complicated features (lines, rectangular pockets, odd diameter circular pockets, hole patterns, etc.)

- Variety of supporting tools and equipment

-

Clausing CNC Knee MILL with Accurite G2 Control Unit

Clausing CNC Knee MILL with Accurite G2 Control Unit

Used for manually machining components in 2D and 3D

- Can be used manually to create simple rectangular geometries

- Can be used semi-automatically with conversational control to do more complicated features (lines, rectangular pockets, odd diameter circular pockets, hole patterns, etc.)

- Can use .nc files to run in full 3-axis mode with a single tool

- Variety of supporting tools and equipment

-

Clausing lathe (15″)

Clausing lathe (15″)

- Used for machining round symmetrical components

- Variable speed up to 1200 rpm

- Can machine stock from 3/64” to 12” diameter

- 40″ between Centers

- Two axis digital readout

- Two axis auto-feed

-

Dake-Johnson vertical band saw

Dake-Johnson vertical band saw

- Used for rough-sizing metals and some plastics

- Multiple clamping options for flexibility

- Hydraulically powered table feed

-

Ellis drill press

Ellis drill press

- Used for making holes in both wood and metal

- Digital spindle speed control

- Multiple clamping options for flexibility

- Many different styles of bits to choose from

-

Ellis horizontal band saw

Ellis horizontal band saw

- Used for rough sizing metal stock, especially long pieces

- Blade tilts for making miter cuts

- Adjustable feed rate and blade speed

- Multiple clamping options for flexibility

-

JD squared pipe bender

JD squared pipe bender

Used to make accurate bends in square and round tubing

- Bends round tubing that is 1/2” to 2 1/2” diameter

- Bends square tubing that is up to 1 1/2” diameter

- Bends schedule 40 pipe up to 2” in diameter

- Uses 10 ton pneumatic cylinder

-

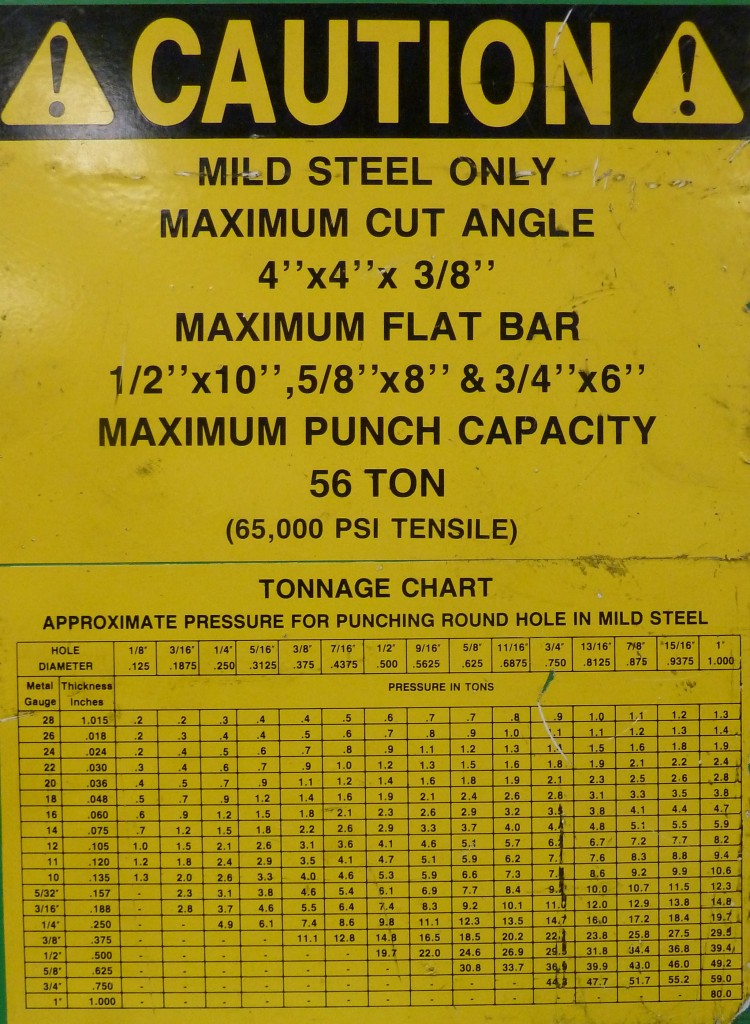

Uni-hydro iron worker

Uni-hydro iron worker

Used for punching, shearing, notching, and bending mild steel

- Capacity up to 56 Tons

- Can shear pieces up to 10″ wide and up to 3/4″ thick (exact capacity dependent on size and tonnage requirements)

- Can punch holes in materials less than an inch (size depends on diameter and tonnage)

- Can notch materials up to 3/8″ thick

- Workpiece may be deformed slightly from the operation

Many different dies to choose from

Dies available for the UniHydro Iron Worker

Round Die

Rectangle Die

Hexagonal Die Chart displaying maximum working limits for different materials

-

Baileigh 75 ton hydraulic press (HSP-75A)

Baileigh 75 ton hydraulic press (HSP-75A)

Hydraulic press for removing or installing press-fit components and bending components

- 75 Ton Capacity

- 31″ Working Width

- 9.8″ Stroke

- 24″ Wide bending attachment for bending sheet metal available

-

Tennsmith brake

Tennsmith brake

Used for bending sheet metal and some plastics

- 50″ max bending width

- Maximum working thickness is 12 gauge mild steel

-

Tennsmith shear

Tennsmith shear

Used for cutting sheet metal and some plastics

- Cut width up to 50″ wide

- Cuts up to 16 gauge mild steel

- Cuts up to 20 gauge stainless steel

- Cuts up to .09″ aluminum

-

Tennsmith notcher

Tennsmith notcher

Used to make notches in sheet metal

- Notches will be “V” shaped with 90° corner

- Sheet metal may exhibit some distortion after notching process

-

Haas Vm2 CNC mill

Haas Vm2 CNC mill

Used for quickly machining complex components out of metal stock

- Machines 2D or 3D components

- 10,000 RPM Spindle

- Indexer may be installed to allow rotation of workpiece about a fourth axis in small increments

- Bed travels 30” (X-axis) by 20” (Y-axis) by 20” (Z-axis)

- Uses MasterCAM .NC code to program component geometry

Welding and grinding equipment

-

Dayton grinding and polishing center

Dayton grinding and polishing center

- Used for cleaning and de-burring metal components

- Wire wheel used for removing rust, gasket material, etc.

- 2 different roughness stone wheels used for removing material from ferrous metals only

- Polishing wheel for making smooth surfaces or de-burring softer metals

-

Kalamazoo disc grinder with dust collection

Kalamazoo disc grinder with dust collection

- Used for smoothing edges and de-burring metal components

- Produces smoother finish than bench grinder

-

Hypertherm plasma cutter

Hypertherm plasma cutter

- Used to make clean accurate cuts in metal up to 3/4”

- Can cut up to 22” per minute when cutting mild steel

- Can be paired with PlasmaCAM CNC table

-

Miller Dynasty 200 tig welder

Miller Dynasty 200 tig welder

- Used to weld both steel and aluminum

- Welds steel that is 0.004” to 0.25” thick

- Welds aluminum that is 0.02” to 0.25” thick

-

Millermatic 300 Mig Welder

Millermatic 300 Mig Welder

Used to weld mild steel. Can be used to weld aluminum or stainless steel with the special setups.

- Welds steel that is 22 gauge up to 1/2” thick

Miller Spoolmatic Spool Gun

Miller Spoolmatic 30A Spool Gun can be attached to the Millermatic 300 MIG welder to weld aluminum up to 1/4” thick. Wire diameter from 0.025” to 1/16” may be used.

-

Millermatic 355 aluminum mig welder

Millermatic 355 aluminum mig welder

- Welds Aluminum that is 18 gauge up to 1/2” thick

-

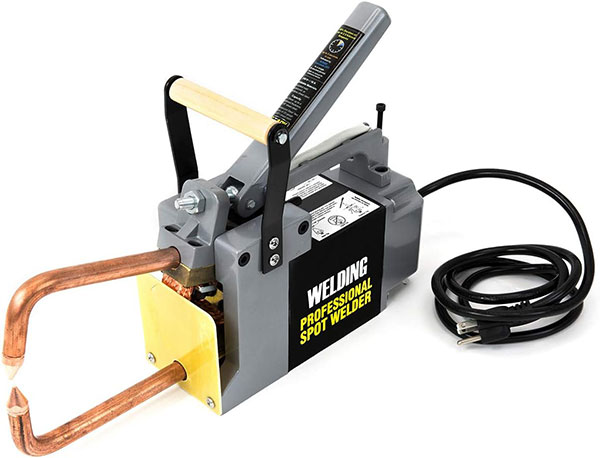

Stark USA Spot Welder

Stark USA Spot Welder

Used for spot welding thin materials together

- 1/8″combined thickness capacity

- Used to spot weld uncoated mild steel, galvanized steel, or stainless sheet steel

- Throat depth 6″

-

Miller Oxy-Acetylene Cutting Torch

Miller Oxy-Acetylene Cutting Torch

Used for cutting, welding and brazing metals

- Produces rough edged cuts that must be finished by grinding or sanding

- Different tips available for different operations

- Can be used to heat parts