Orientation

Print orientation effects almost all aspects of the print, including part surface quality, part strength, tolerances of certain part features, print time, support material used (thus cost), and ultimately the changes of a successful print. Proper orientation is key to part success. If a specific orientation is needed for functional reasons, this needs to be noted when submitting a job, otherwise the orientation that maximizes part success chances and minimizes cost will be chosen.

Some orientation considerations are:

- Large horizontal areas that are overhung/not in contact with the print bed will need support, affecting the surface finish.

- Stair-stepping occurs on shallow angled surfaces

- Adding Z-height dramatically increases print time

- Layers will create natural shear-planes and should be oriented so they don’t impact part performance

- Holes will print better if they are perpendicular to the build plate

Part Design

3D printing is a manufacturing process like any other. Like other processes, it has its own limitations and design requirements; not all parts can or should be printed.

Some design considerations are:

- Where possible, build parts with self-supporting geometry. That is, geometry that tapers at a minimum of a 45-degree angle.

- Avoid large horizontal overhangs

- Design walls and other features to be a multiple of .4mm so that the printer can do an even number of passes and avoids having to “fill” internal areas

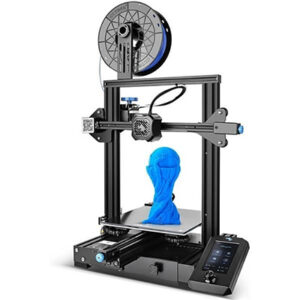

Hobby-Grade Printer: Ender 3 v2

Hobby-Grade Printer: Ender 3 v2

Industrial-Grade Printer: Fortus 250

Industrial-Grade Printer: Fortus 250 Industrial-Grade Printer: Fortus 450

Industrial-Grade Printer: Fortus 450