Surface roughness evolution of medical implant alloy

Objective

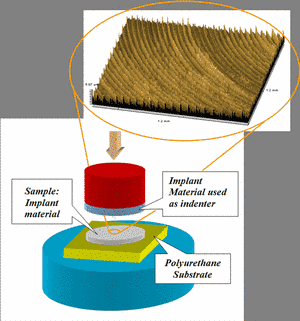

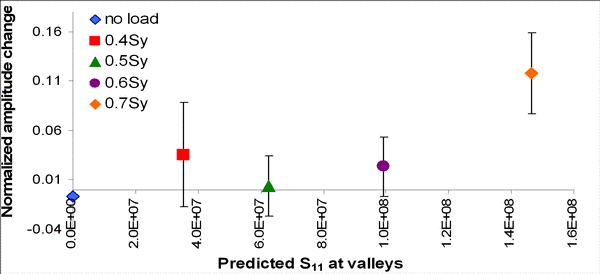

- Characterize the stress-assisted dissolution mechanism at modular joint implant interface

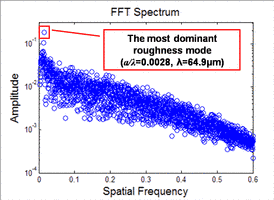

- Characterize the roughness evolution by combination of contact and corrosion

Motivation

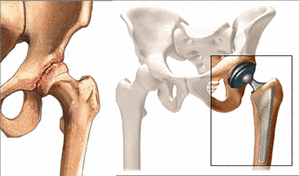

Modular implant and surface failure due to cyclic contacts between modular interlocked rough surfaces by human behavior in corrosive physiological fluid

- Biocompatibility problem ex) inflammation and necrosis