Overview

The objective of this research is to assess the performance of users in a large space virtual environment equipped with haptic interaction. To achieve this objective, a new method of using a haptic device in a large space virtual environment will be developed. The motivating application is the desire to simulate an assembly workspace. The sense of touch is critical to our understanding of how parts are assembled. The long term goal is to be able to prototype assembly methods and validate preliminary assembly wage rate standards in an immersive environment. This capability has the potential to significantly improve products and reduce costs by providing a simulation where manufacturing engineers and assembly workers could better plan assembly operations before building physical prototypes.

Our approach to providing haptic interaction in a large space virtual environment is to combine a six degree-of-freedom haptic device with a mobile powered platform. Large space virtual environments can consist of arrangements of large screen projection systems that support position tracking and stereo viewing or rooms that have large area tracking combined with head mounted displays. Both types of facilities are available at Iowa State University: a 3m x 4m x 3m stereo projection environment and a 13m x 20m room with full position tracking capabilities. A recently purchased six degree-of-freedom haptic device can provide forces within a work area approximately the size of a person’s reach envelope. Placing the haptic device on a mobile platform will allow us to use this haptic device in the projection screen environment as well as the large area tracked room. The mobile platform will be position tracked so that we can control the relative movement of the haptic device with respect to the user. The intent is that the user would not actively move the platform around the space, but that the mobile platform would be intelligent enough to follow the user as he/she moves around in the space. Our test application will be to build an assembly workspace equipped with benches, skids, bins, and cranes that fits into a 3m x 4m x 3m workspace. Study participants will be asked to perform an assembly operation consisting of selecting parts, fixturing parts, assembling parts and moving them to the assembly line. Ergonomic and timing studies will be performed to assess the effectiveness of the immersive experience. These studies will be performed in the projection screen environment and in the position tracked room.

The successful completion of this research has great potential to improve product design. With the expansion of force feedback to encompass the full area of an assembly workstation, virtual reality technology can be used by manufacturing engineers to prototype how humans interact with products during part assembly, long before the first part reaches the assembly station. Using CAD models and haptic devices in a large scale virtual environment, product design teams can explore the human/product/workstation interaction that affects worker ergonomics, fixture and tooling design. Other product designers can explore human/product interaction as they design safety measures and develop maintenance methods. In-depth evaluations using CAD models early in the design process can save re-work and re-design which add unnecessary costs to the final product.

The integration of projection systems, computer graphics, tracking systems, haptics and robotics requires a multidisciplinary design approach. Knowledge of computer science, electrical engineering, software engineering, and mechanical engineering is essential to the success of this research. As a part of this award, the PIs will engage students from these disciplines in the research. As a result, these students will experience a meaningful multidisciplinary design project and leave with an understanding and appreciation for the knowledge that can be contributed from people who come from different disciplines.

Media

- Nexus Mobile Robot

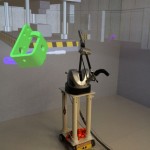

- Haption Virtuose on Nexus Mobile Robot

- Video: Combining Haptics with an Omnidirectional Mobile Robot

Personnel

- Ryan A. Pavlik – Graduate Research Assistant, Iowa State University

- Dr. Judy M. Vance, Joseph C. and Elizabeth A. Anderlik Professor of Engineering, Iowa State University

- Dr. Greg R. Luecke, Associate Professor, Iowa State University

Funding

- National Science Foundation – Grant Number: CMMI-1061458